Production

Progressive Stamping

The right tool, the right production technology and the right materials are imperitive for the quality of the end product. Our experience in the

mass production of precision parts with the selective use of all

stamping raw materials enables us to be the ideal partner for parts with demanding stamping requirements.

MORE

Precision Stamping

Processes for precision cutting and forming are combined to economically produce

precision parts, improve competitiveness, and enable us to produce the

smallest of parts with precision while reducing the number of process

steps.

MORE

Microstamping

Our in-house development work and many years of experience have helped us become a worldwide market leader for microstamping.

MORE

Assemblies

When products require stamped and precision stamped parts or formed parts in

an assembly, Hänggi is the right partner for you. We have the right

know-how for series production with low and high volumes to be able to

offer you complete solutions. We develop and design complete production

lines and rotary table automation right up to the conditioning or

palletization of the finished product.

MORE

Surface Treatment

Vibratory finishing, barrel-polishing, vibration treatment, deburring with

centrifugal force, polishing, belt grinding, treatment with brushes,

etc.

Fully automatic vibratory finishing centers for economic

production of low and high volume series. Washing and degreasing in

closed systems with environmentally-friendly solvents.

MORE

Production Planning

Inmitten der Fertigung situiert, ist die Arbeitsvorbereitung quasi das „Herz der Produktion“.

AVOR ist ebenso wichtig wie die Produktion selbst, denn erst Planung und Prozesssicherung in jeder Stufe der Fertigung garantieren die Wirtschaftlichkeit des Produktes.

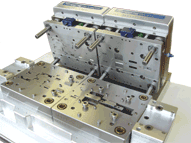

Module Punch

Module punch tool